BAG MAKING MACHINE

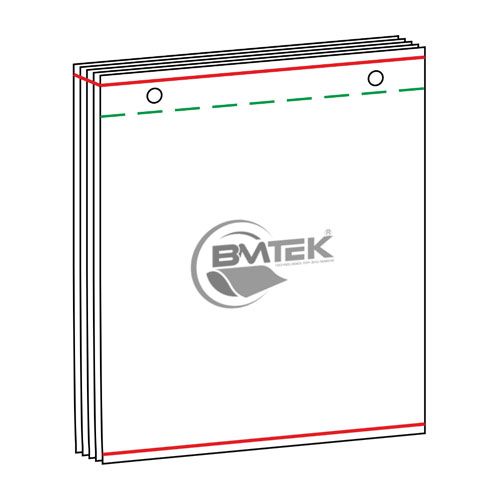

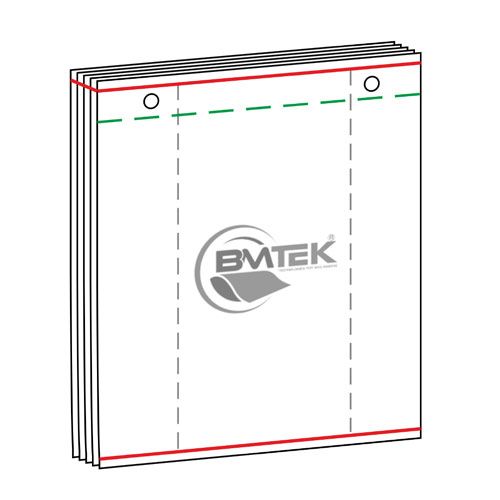

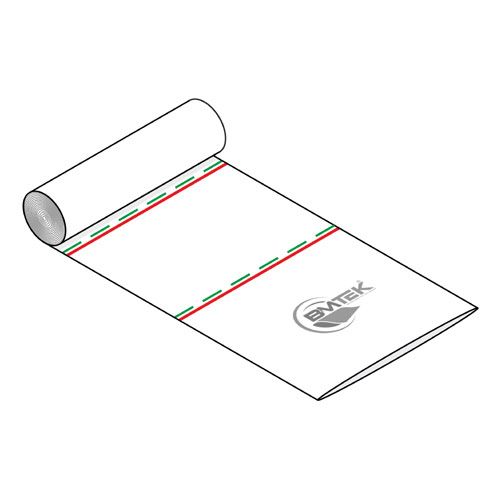

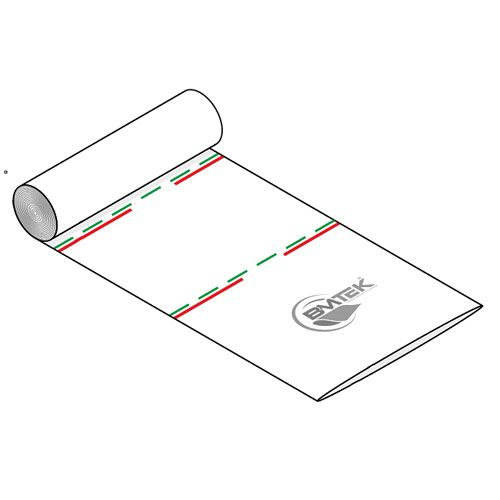

BAGS ON ROLL

BMTEK SBM line is the perfect line for those looking for EFFICIENCY, MODULARITY, FLEXIBILITY AND IMPLEMENTABILITY.

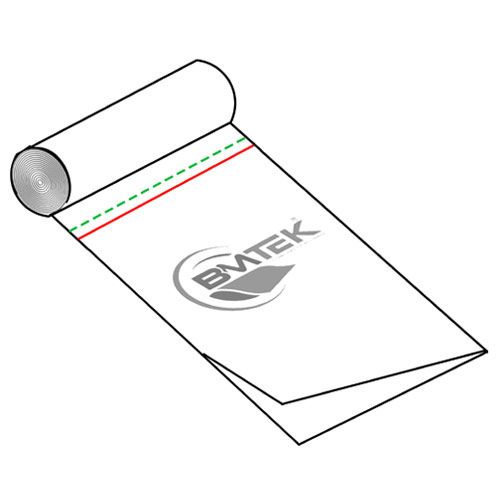

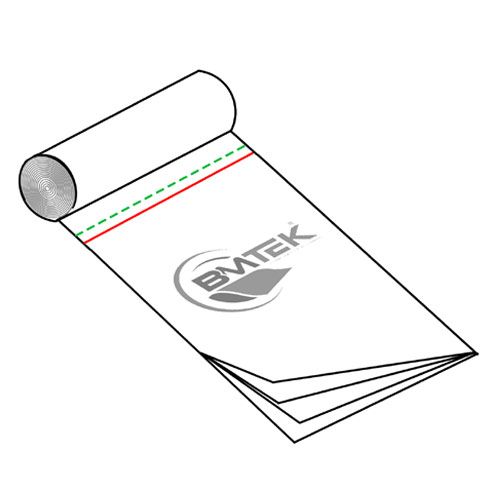

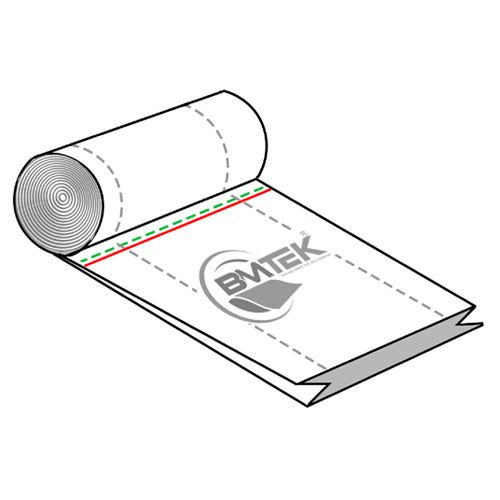

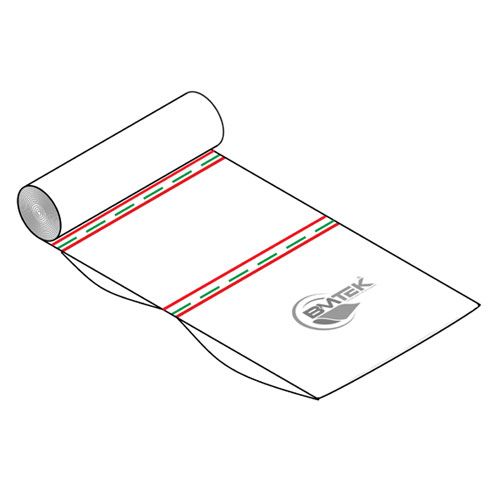

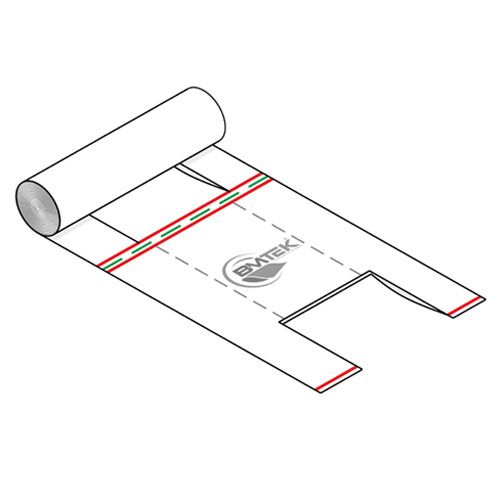

This SBM line is perfect to obtain SHOPPERS on ROLLS.

This Bag Making Machine SBM consists of:

1) MPLR : Motorised shaftless unwinder (in the 1-track version), equipped with two hydraulically driven expanding shafts (in the 2-track version) for easy lifting of the reel.

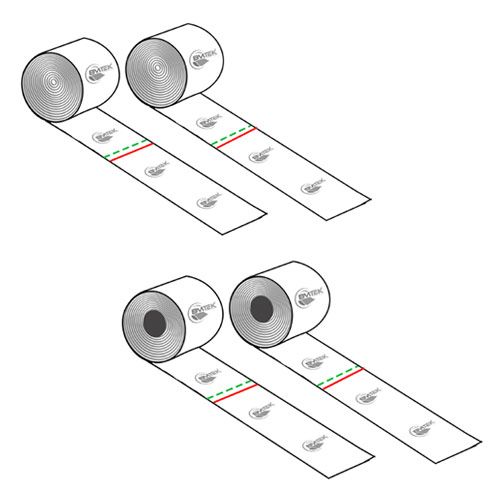

2) LW : System consisting of knives for cutting and welding at a temperature controlled by the operator, to obtain more lanes of productions.

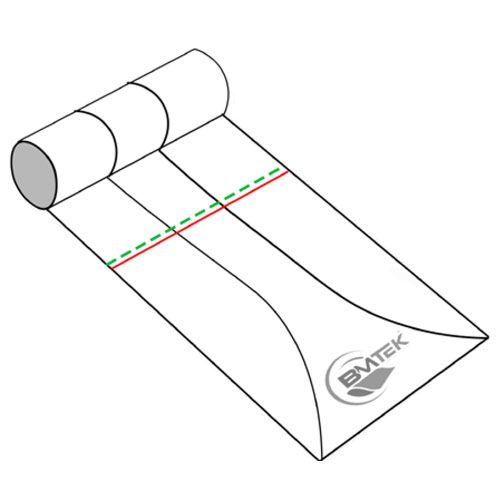

3) GUSSETER : System that allows the conformation of the gusset by means of idle rollers and wooden folding triangles. Possibility of gusseting from 1 to 4 tracks.

4) SBM : Welding machine with an innovative design and concept that give true flexibility to meet the changing demands of the market.

In fact, it offers the possibility of adding a module, increasing the length of the machine so that other accessories can be added over time.

The welding units are also easily interchangeable, ensuring maximum production flexibility.

- 5) FLEX system : to obtain the shopper cut;

- 6) Pneumatic perforator : to obtain bags perforated in the desired position through tools of different diameters;

- 7) Compensator : to adjust the position of machining inside the machine;

8) SR UNIT : System to obtain “V” and “C” fold.

9) DMW : fully automatic winding unit. Designed to work with two lanes, equipped with forks to wind the film, no stop production system, and a perforation braking system, and LABELLER.

With this line, it is possible to obtain: